When it comes to choosing LED downlights, most downlight manufacturers highly recommend the COB LED downlights. But what are COB LEDs, and why are they considered superior? If you're in the dark about COB lights and their uses, don't worry. In this post, I'll explain everything you need to know about these innovative light fixtures, including the COB LED definition, their advantages, and their applications.

What is COB Led Downlights?

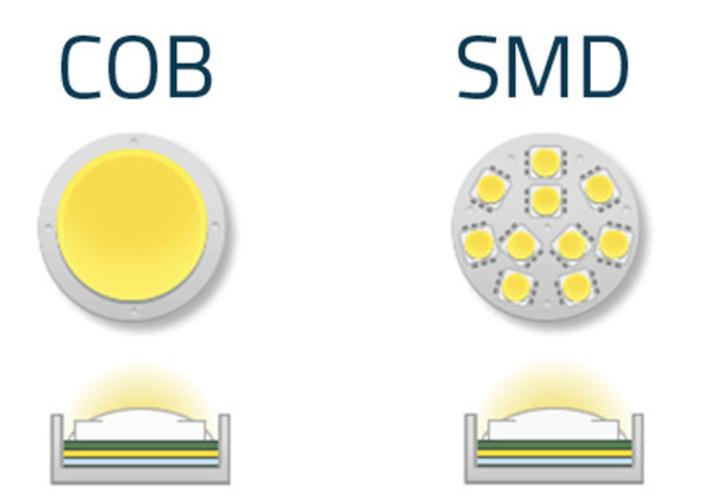

With advancements in the lighting industry, the LED COB downlight has emerged as a superior alternative to traditional LED downlights. Unlike standard LED downlights, a COB LED downlight is essentially a module of multiple LED chips bonded together.

Typically, a COB downlight houses more than 9 LED chips. These chips are mounted internally, optimizing space usage and maximizing light output. When powered, the COB downlight illuminates as a single panel, providing a seamless and uniform light source, unlike multiple individual lights.

What is the Lifespan of A Cob Downlight?

On average, COB LED downlights have an impressive lifespan ranging from 20,000 to 50,000 hours. This means that they can effectively serve your lighting needs for up to six years. For instance, the COB LED downlights from Vertex boast a remarkable lifespan of 40,000 hours.

Advantages of Cob Led Downlights

As I mentioned, COB LED downlights bring numerous benefits to the table. But what are these advantages? Let's delve into the specifics of what makes COB LED downlights a superior lighting choice.

More Lighting

Typically, a COB downlight incorporates multiple diodes. This multi-diode arrangement allows the light to provide superior illumination compared to traditional downlights. Moreover, due to the multiple LED chips, it achieves higher light output while consuming less electricity.

Less Failure Rate

Two factors contribute to the lower failure rate of COB downlights. Firstly, COB downlights have fewer welding points, reducing the chances of failure. Typically, the fewer joints a light has, the less likely it is to fail. This is because each chip in a COB downlight is directly mounted onto the substrate, ensuring smooth operation.

Secondly, COB downlights excel in heat dissipation. COB LEDs utilize a single circuit with just two contacts to power the multiple diode chips they house. This setup allows COB downlights to operate efficiently with fewer chips, and it also provides adequate space for heat to disperse between the chips.

Reduce Electric Cost

Because of the unique installation method of the chips, the chip easily is mounted in an outside heat sink. If you keep surface cob downlight at a set temperature, the lights could run longer time.

The Disadvantages of Cob Led Downlights

As an old saying said, nothing is perfect. The cod led downlights still have disadvantages.

Need Well-Engineered Outside power Source

Because of the unique lighting arrangement, the led cob down light requires a stable current and voltage, in case of damaging the diodes.

A Well-Designed Heat Sink

Although the mounted chip could reduce a certain of energy, the diodes are still being destroyed due to the improper placement of the heating element. It is because the improper placement of the heating sink would cause the overheating.

Low Repairability

This drawback is the most important factor that you need to notice when you are planning to purchase for your project. When one of the downlight cob light chips is damaged, the entire cob led must be substituted with a newer one. As for the SMD LEDs, when one fails, it can be easy to be changed.

Which is better? COB LED or SMD LED?

Talking about the led SMD downlight, the comparison between SMD and COB is inevitable to be put into this post. I will compare them from multiple perspectives.

Definition

Smd led downlight (Surface Mounted Device LED Downlight) has a versatile electronic component that could be permanently fused to a printed circuit board. The SMD LED is widely applied to the light bulbs, string lights, and phone notification lights.

The cob downlights(Chip on Board downlights) is the advanced light in the LED lighting industry because they could make more effective energy use. Typically, the COB chips feature 9 or more diodes. But, no matter how many diodes, the cob downlights still have only a circuit and two contacts, shaping the panel look of COB LED lights.

Although these two types of lights have similarities in the diodes, the COB LED has more diodes.

The cob downlights(Chip on Board downlights) is the advanced light in the LED lighting industry because they could make more effective energy use. Typically, the COB chips feature 9 or more diodes. But, no matter how many diodes, the cob downlights still have only a circuit and two contacts, shaping the panel look of COB LED lights.

Although these two types of lights have similarities in the diodes, the COB LED has more diodes.

Brightness

The brightness is the most significant difference between them. Although they both are LED lights, the brightness of the lights are determined by the lumen output of the related chips. The SM applies 50 to 100 per watt, while the lowest measure of COB is 80 lumen per watt. Therefore, in this competition of brightness, the cob led downlights are brighter than led smd downlight.

Color Temperature

The smd led downlight is more adaptable and provides a larger range of options in color and color temperature. Because the diodes with three primary colors(red, green, or blue) are used in the smd down light, you could get any color from the smd downlight by changing the output level.

However, the COB has a limited capability of adjusting the colors and color temperature. Therefore, the led cob downlight is not adjustable.

However, the COB has a limited capability of adjusting the colors and color temperature. Therefore, the led cob downlight is not adjustable.

Why Are Cob Led Downlights Yellow?

This question involves many aspects. Here are the main reasons why you look the cob led downlights yellow.

First, you may actually look at a phosphor (a substance that absorbs light of one color and emits it again in another color) known as cerium-doped yttrium-aluminum garnet (Ce:YAG).

Second, led downlights cob may affected by the color temperature. The color temperature of an LED light is measured in Kelvin (K). Lower color temperatures, such as those around 2700K to 3000K, tend to emit warmer and more yellowish light. If your cob Led downlights have a color temperature in this range, they will produce a more yellow light compared to higher color temperatures which emit cooler, bluish light.

Third, led downlights cob may relates to the Color Rendering Index (CRI). The CRI measures how accurately a light source reproduces colors compared to natural light. Lower CRI values can result in a less accurate representation of colors. Some cob Led downlights with lower CRI values might make colors appear more yellowish or less vibrant.

Fourth, led downlights cob may determined by the aulity and manufacturing variability. The quality of the cob led downlights, the manufacturing process, and the materials used can all impact the actual color emitted. Cheaper or lower-quality COB LEDs might exhibit color variations that lead to a yellowish appearance.

First, you may actually look at a phosphor (a substance that absorbs light of one color and emits it again in another color) known as cerium-doped yttrium-aluminum garnet (Ce:YAG).

Second, led downlights cob may affected by the color temperature. The color temperature of an LED light is measured in Kelvin (K). Lower color temperatures, such as those around 2700K to 3000K, tend to emit warmer and more yellowish light. If your cob Led downlights have a color temperature in this range, they will produce a more yellow light compared to higher color temperatures which emit cooler, bluish light.

Third, led downlights cob may relates to the Color Rendering Index (CRI). The CRI measures how accurately a light source reproduces colors compared to natural light. Lower CRI values can result in a less accurate representation of colors. Some cob Led downlights with lower CRI values might make colors appear more yellowish or less vibrant.

Fourth, led downlights cob may determined by the aulity and manufacturing variability. The quality of the cob led downlights, the manufacturing process, and the materials used can all impact the actual color emitted. Cheaper or lower-quality COB LEDs might exhibit color variations that lead to a yellowish appearance.

Are Cob Led Downlights Dimmable?

Yes, the yare dimmable. In Vertex, all the cob led downlights are dimmable. Some cob led downlights are triac dimming, 0-10V/1-10V, DALI etc; Some cob led downlights can be dimmed via app control.

Conclusion

All in all, the led cob down light is a practical lighting device at a reasonable price. It is the new trend in house decoration and office design. If you are hunting for the cob led downlight , you could contact Vertex, a professional downlight supplier.

Established in 2000, Vertex puts all its effort into research and developing the commercial downlight. Cob led downlights are one of its most proudly products, because the cob led downlights in Vertex are the function and aesthetic combination. Cob led downlights not only produce soft and even lighting but also splendid with the house decorations very well.